| |

| SAW GINNING FEED BAR (STEEL) |

| |

| We provide a wide range of export quality Saw Ginning Machine STEEL FEED BAR, for Bajaj Continental egale, lummus saw gin machine & other Saw gins brand models, 100 % VMC machining feed bar. this feed bar Used in lummus saw gin, Continental saw gin, and other brands saw gin models. Our feed bar are made as per international quality standards. We Export Our Saw Ginning Machine Feed bar In African continental Like Uganda, Tanzania, Madagascar, Kenya, Malawi, Zambia, Mozambique, Togo, Senegal, South Africa, Nigeria, Benin, Ivory Cost Or other African countries, Also we Started export to UAE, Turkey, & USA saw gin parts traders. Our feed bar details are as below: |

|

| We are supplier & exporter of best quality feed bars for saw ginning machine, we supply high quality steel feed bar in to market, this feed bar is used in many saw gin machinery like lummus saw gin, murry saw gin, continental saw gin or more. we sale this feed bar many ginning companies if africa, turkey or more countries. |

| |

| STEEL FEED BAR : SAW GIN LINT CLEANER PARTS |

|

| Feed bar for lummus, continental, murray, cherokee machinery, this feed bar is 100% made with high quality steel material, with lab tested raw material. also we provide 3rd party inspection before loading material or dispetch. we have sgs and buraeu veritas company for inspection. |

| |

| STEEL FEED BAR : SAW GIN LINT CLEANER |

|

| The feed bar is available for all saw ginning machinery, 100 % v.m.c machining feed bar, easy feeting in lint cleaner machine, low price is we compair with other countries price. |

| |

| STEEL FEED BAR : MANUFACTURING PROCESS |

|

| Here we see manufacturing process of this saw gin feed bar, first we slect raw material which are perfact for this feed bar, afrer we cut it in proper sizing with automatic cutting machine, before we starting machining raw material is checked by automatic level check system, if any surface is nor proper or uneven than this system check and clear it with turning process. this feed bar is machining with automatic V.M.C machine 100 % accurate all angle. |

| |

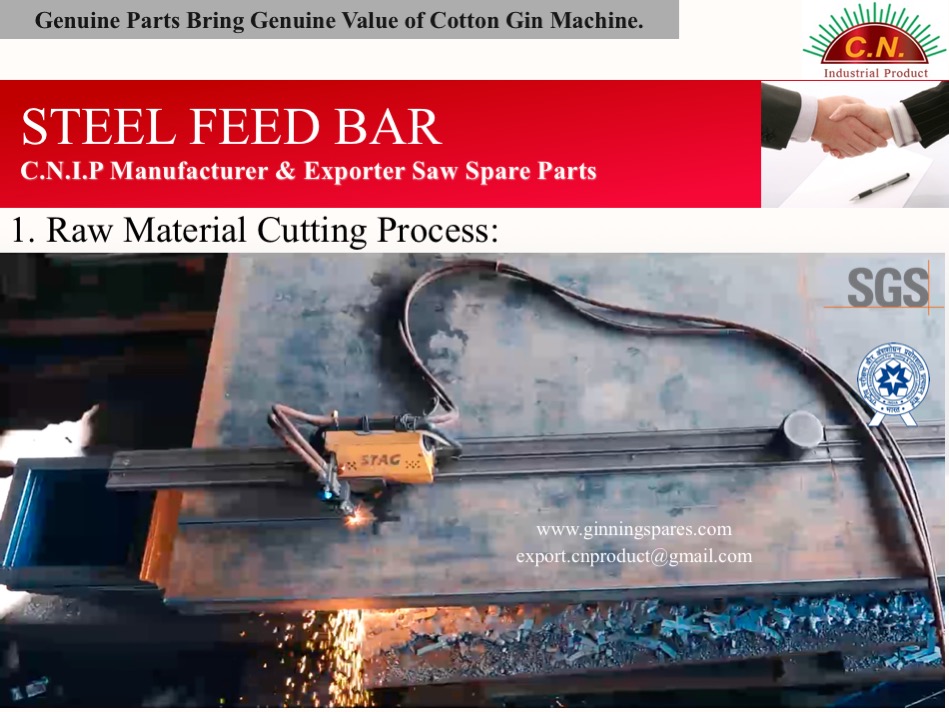

| STEEL FEED BAR : RAW MATERIAL CUTTING PROCESS |

|

| Raw material plays a very important role in making any part, if the material is not used well or the material is not checked properly then the quality of the parts is not good, so we report lab test of each of our raw material, So know the quality of raw material before machining. |

| |

| STEEL FEED BAR : MATERIAL LEVELING CHECKING PROCESS |

|

| If the surface of the raw material is crooked when it is cut, it is necessary to check the surface before machining, so we check the level of the raw material before we make this feed bar, and even more than 1 mm. Also checked in small size. So that we can give good quality parts to our customer. |

| |

| STEEL FEED BAR : All SIDE SURFACE CUTTING |

|

| Surface machining is the first step in making a feed bar, it is machined until the 6 sides of the feed bar are at the same level then it is checked again with a micro meter to make sure that the raw material Perfect size has arrived. |

| |

| STEEL FEED BAR : RADIUS CUTTING PROCESS |

|

| An important part of the feed bar is its readiness, if the readiness is not correct it does not fit properly in the lint clearer and at the same time there is a lot of difficulty in passing the cotton, so we make the readiness in a fully automatic machine. So that there are no defects left in the feed bar, it is re-checked after it becomes ready, and if there is any mistake in it then it is corrected immediately. |

| |

| STEEL FEED BAR : SLIDE CUTTING PROCESS |

|

| We also make slide cutting in V.M.C machine so that there is no change in any size, this slide is according to the customer's given drawing and it is also checked with a laser machine. |

| |

| STEEL FEED BAR : GALVANIZING PROCESS |

|

| In order to preserve the feed bar for a long time after its formation, we process galvanized crosses so that the feed bar does not get any kind of corrosion. |

| |

| STEEL FEED BAR : PACKING |

|

| Packing in wooden box with, bubble plastic raping and thermocol protected box. |

| |

| PLEASE CONTACT US OR EMAIL US ON : export.cnproduct@gmail.com |

| |

|

| |